Premier Automatic Frame Clamp

Designed for high volume advanced assembly of window frames. Sub- assembled window frame components are placed in the machine which then squares, clamps, fastens and discharges a completed frame for further assembly operations. Capable of producing 1,200 to 1,500 frames per shift.

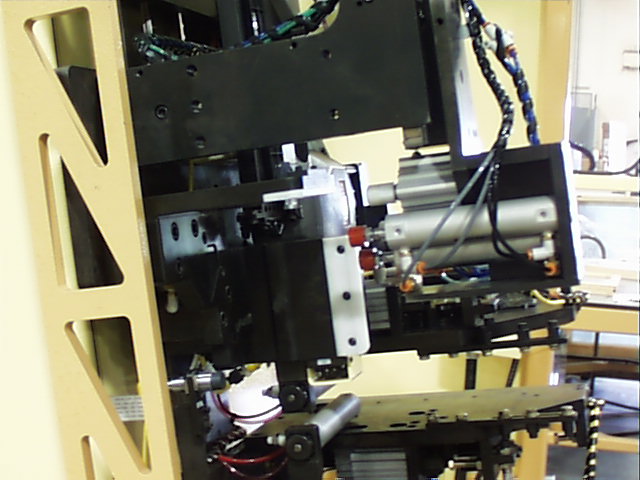

Finish nailers, staplers, or screwdrivers may be mounted to fasten a number of corner joint styles. Fastener placement is determined by your product specifications. The four fastening modules include tools, square and down clamps, safety sensors and fastener placement controls. Powered adjustment places the fastener modules for product height and width sizes within specifications. The power adjustment keeps the frame square, true and vertically centered at a most convenient working height for operations. This machine can produce an assembled frame every 15 to 20 seconds. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy-duty frame

-

Precision linear bearings

-

Low maintenance

-

Powered size adjustments