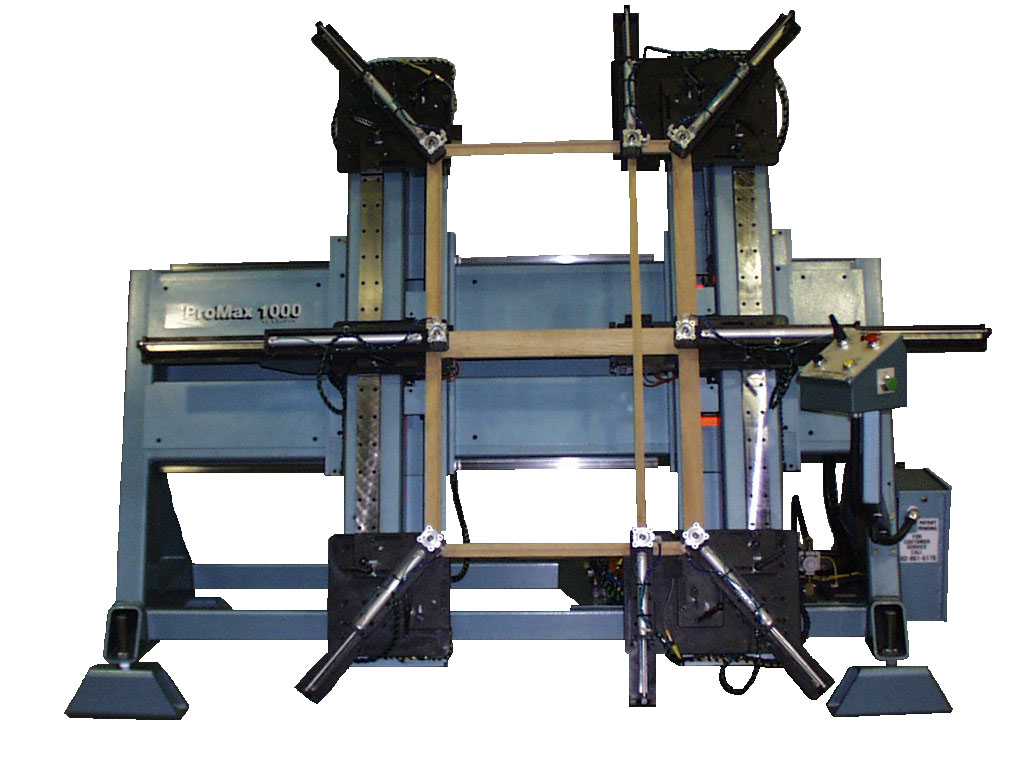

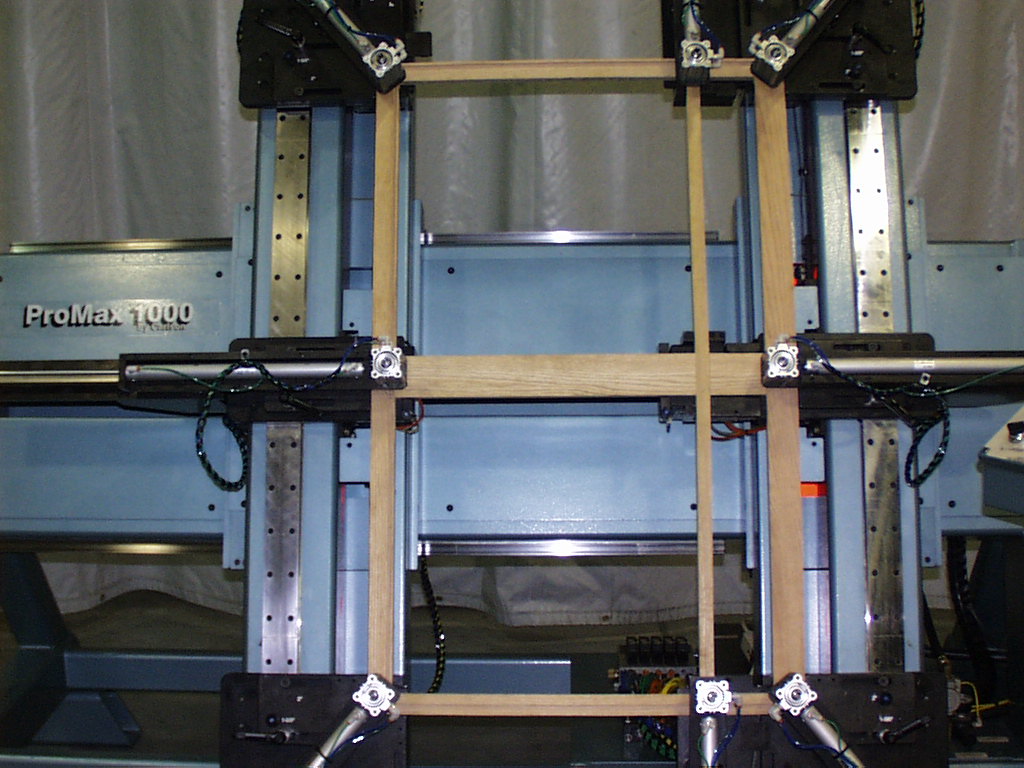

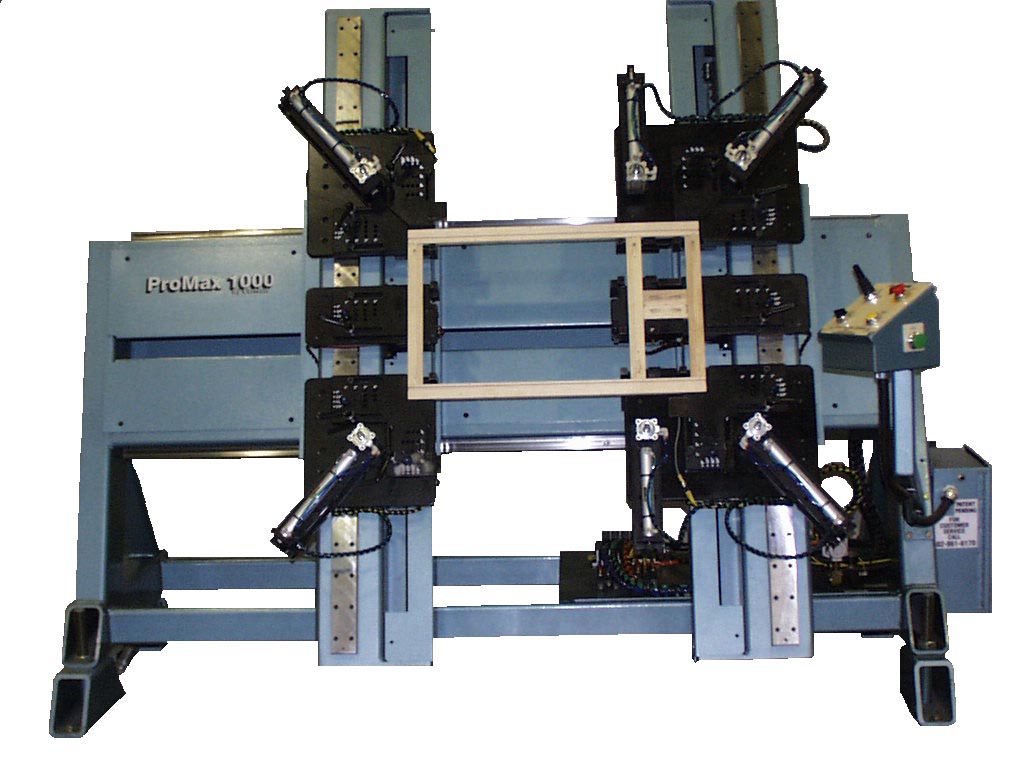

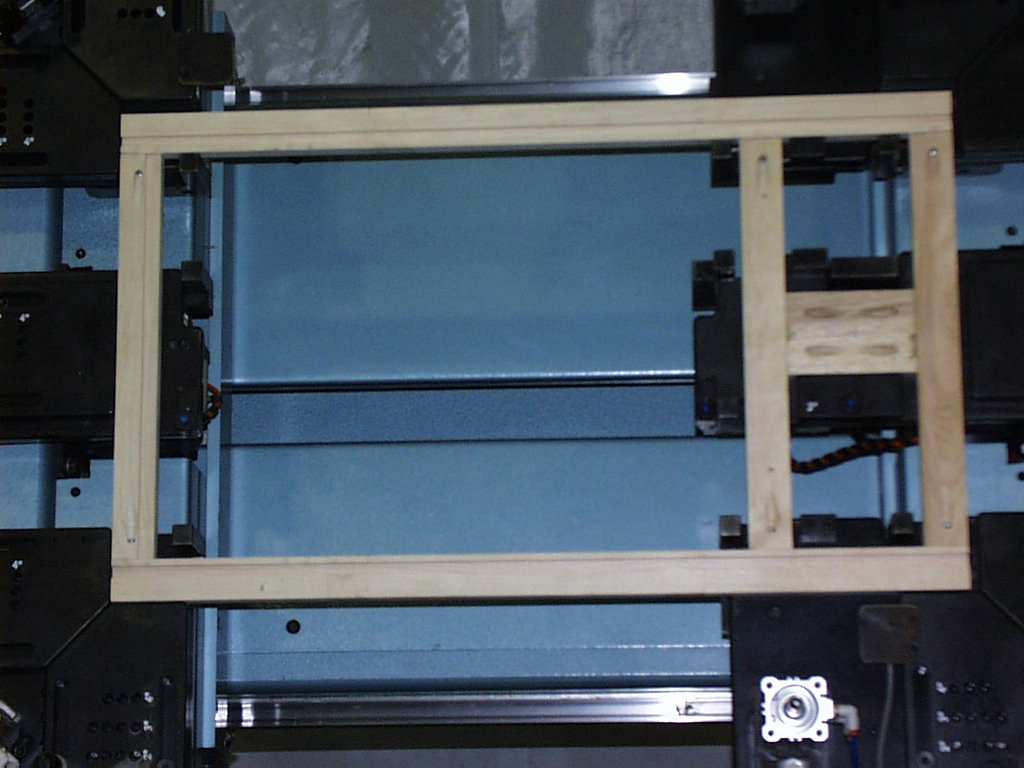

ProMax Face Frame Assembly Machine

The ProMax Face Frame Assembly Machine is an affordable system that squares and clamps common sizes of base and wall cabinet face frame material allowing manual fastening procedures. Production rates of 300 to 400 frames per eight hour shift are possible depending upon the frame configuration. Standard joy stick operation allows quick and accurate size adjustments. Down clamps are included to insure flush joints prior to fastening. The frame is ergonomically designed at an angle for easy placement of sub-assembled frame parts and fast removal of the finished product. Operating controls are simple and convenient to minimize training time. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

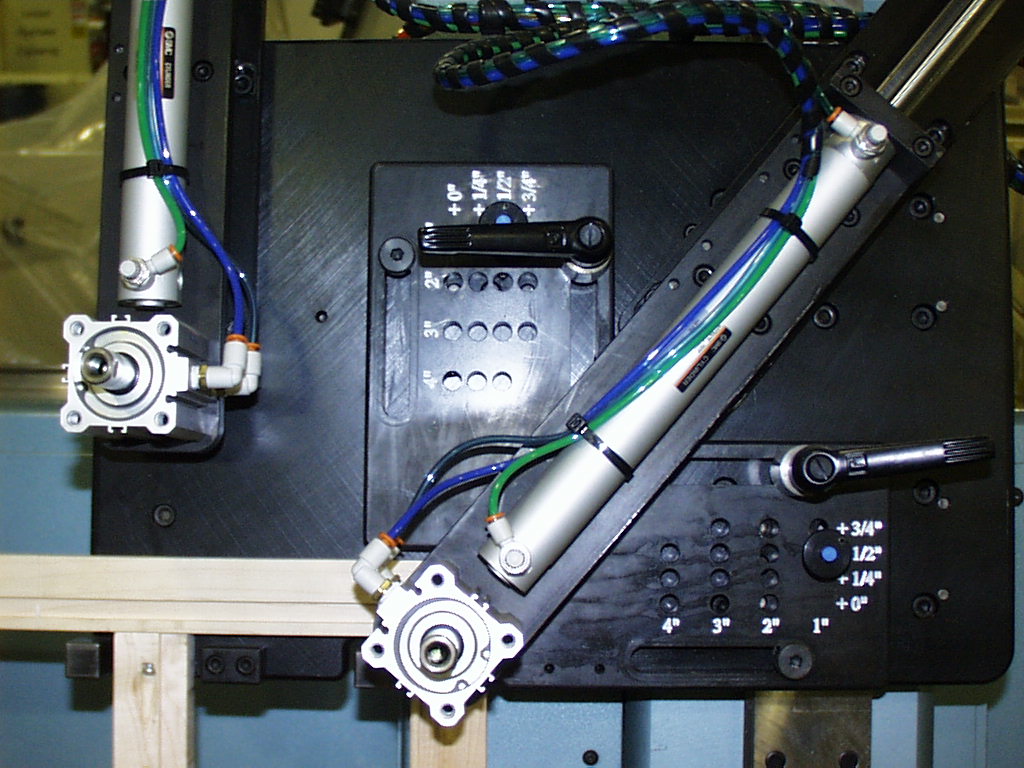

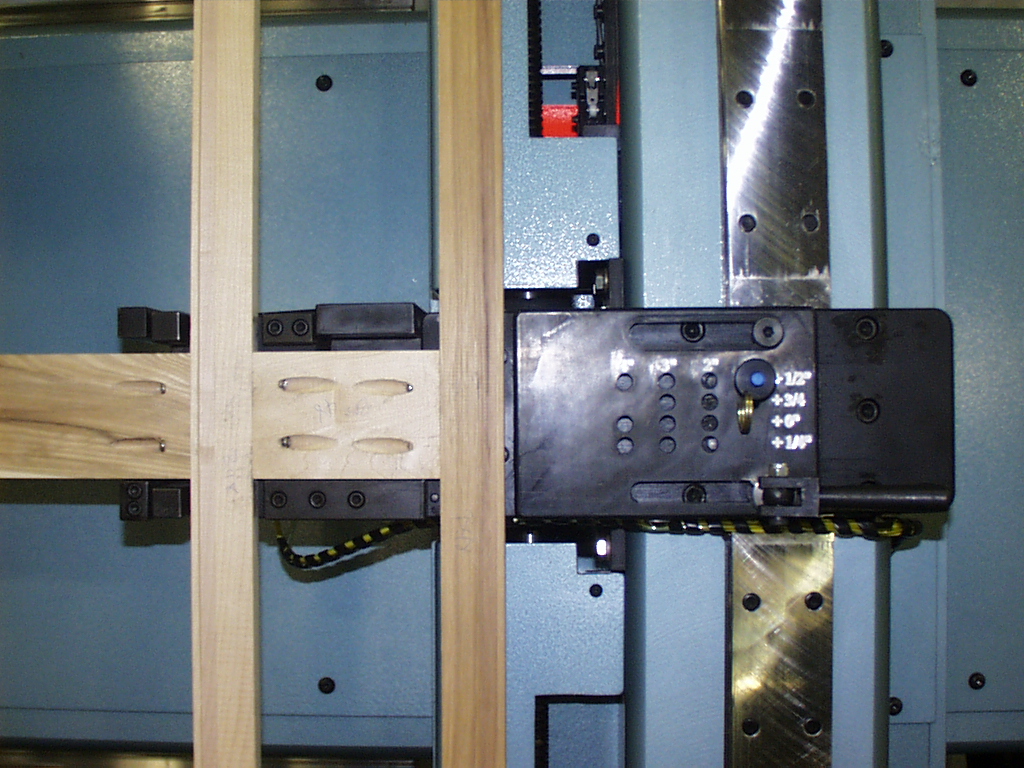

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller