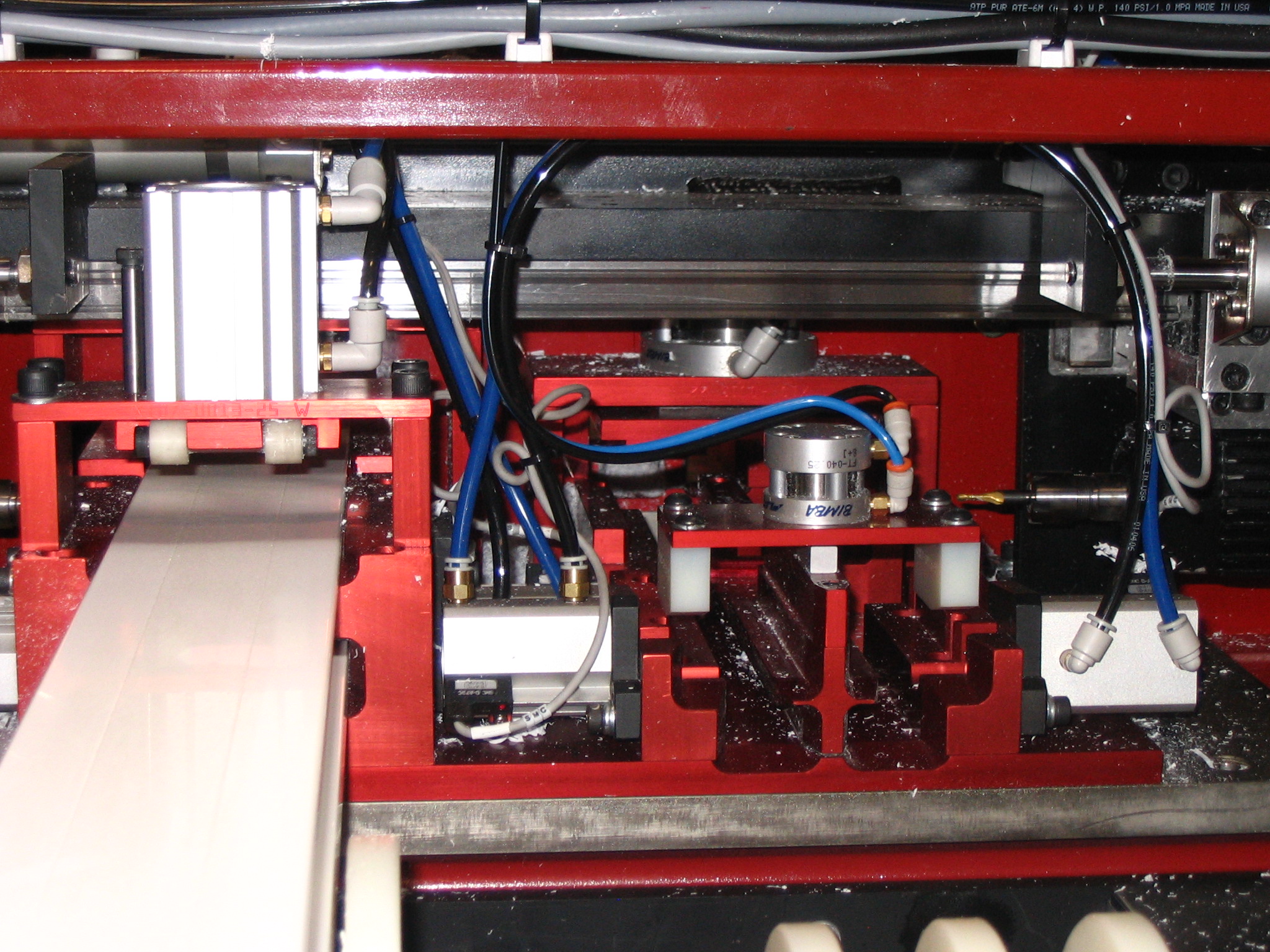

Meeting Rail/Mulling Machining Center

-

Highly efficient fabrication center to automatically cut to length and mill Meeting Rail or T-Mullion components for PVC vinyl, aluminum or fiberglass window systems

-

Designed to efficiently process components for continuous head / sill window systems

-

Completely processes two equal length meeting rails or one mullion per cycle, including secondary fabrication for hardware installation

-

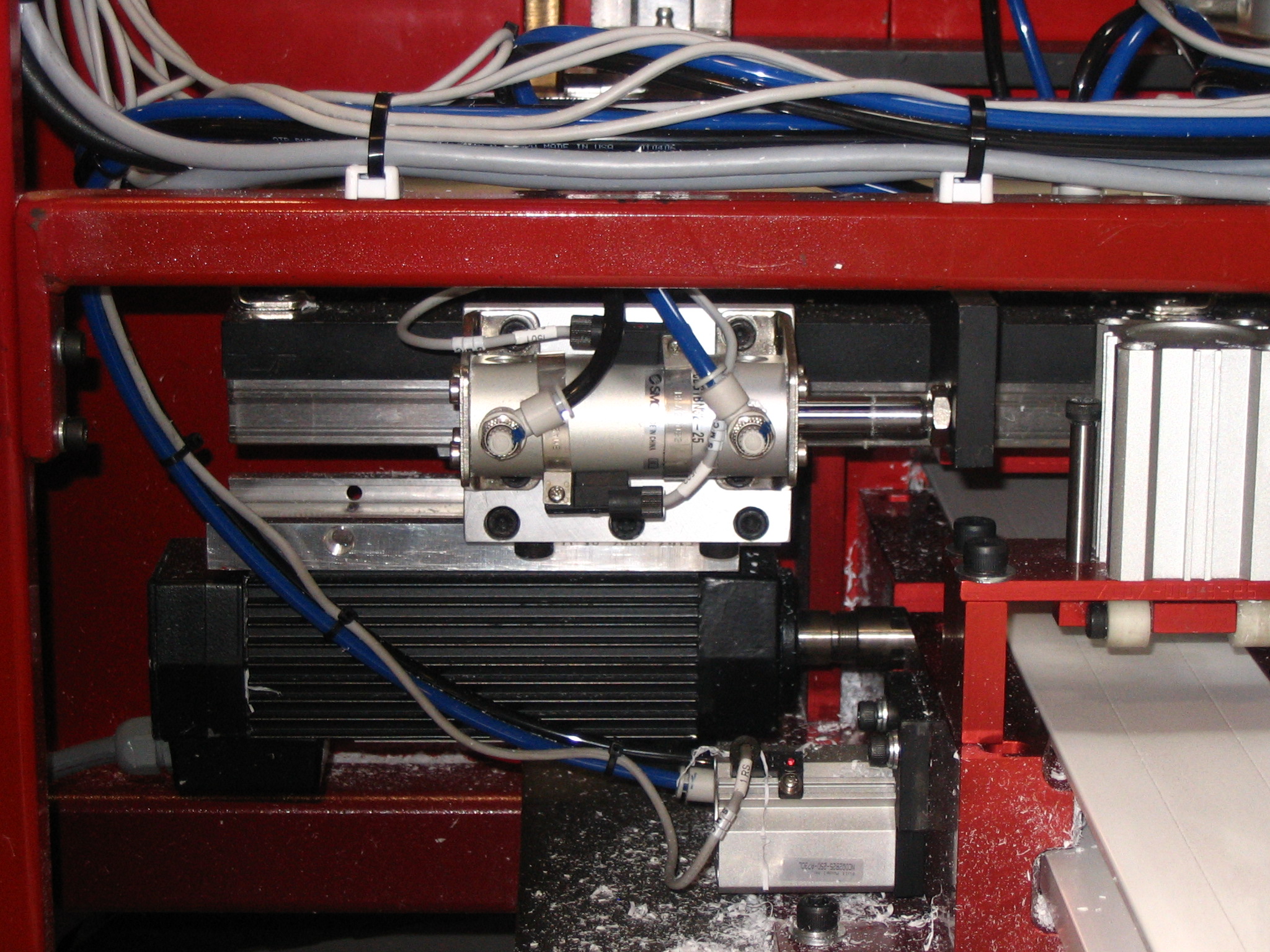

Servo-controlled saw carriage for optimum feed rate to eliminate chipping during processing

-

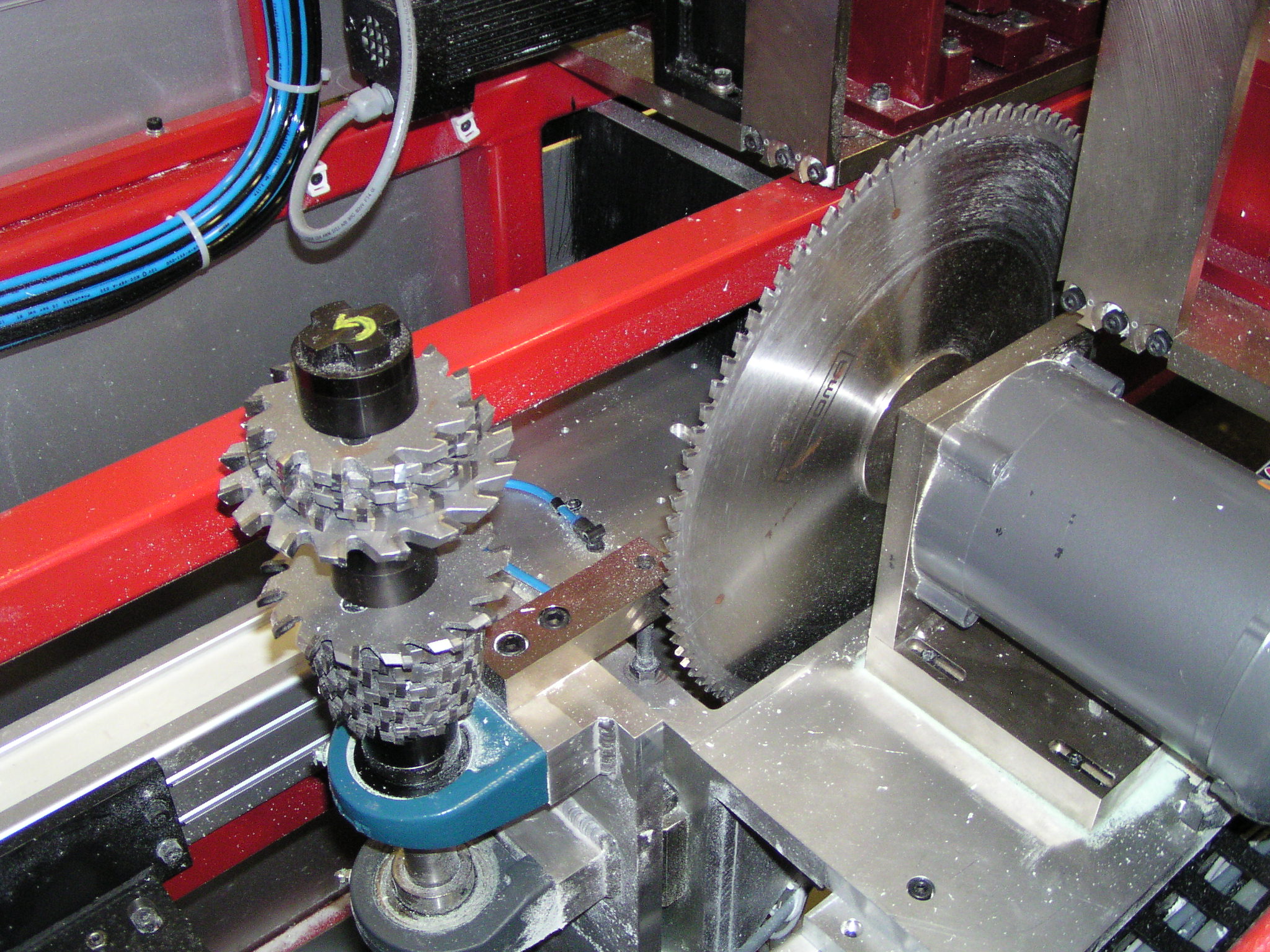

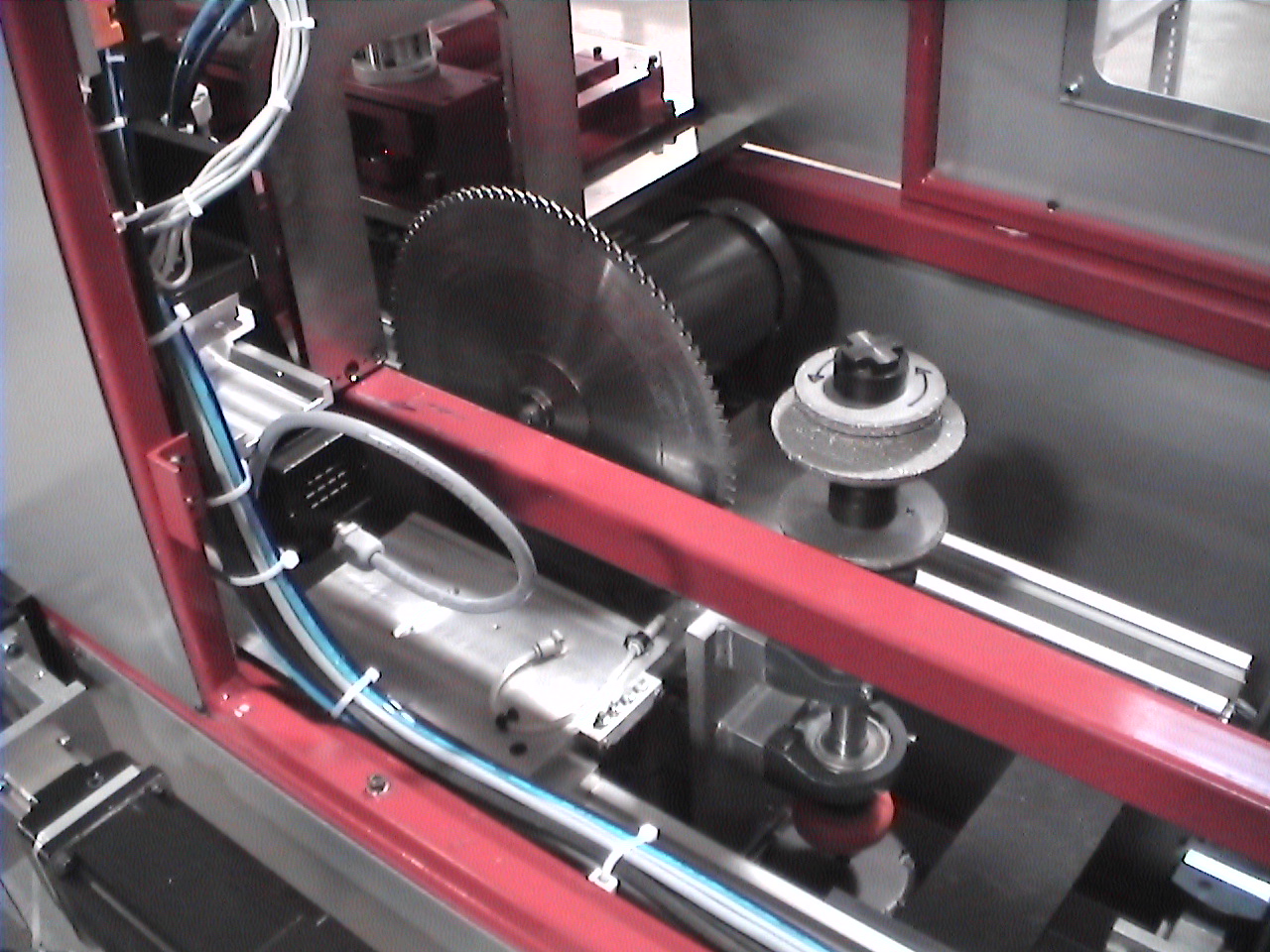

Standard 400 mm (15.75”) diameter carbide-tipped parting blade to cut components to length

-

Integrated pneumatic clamping and control interface spread parts after cutting

-

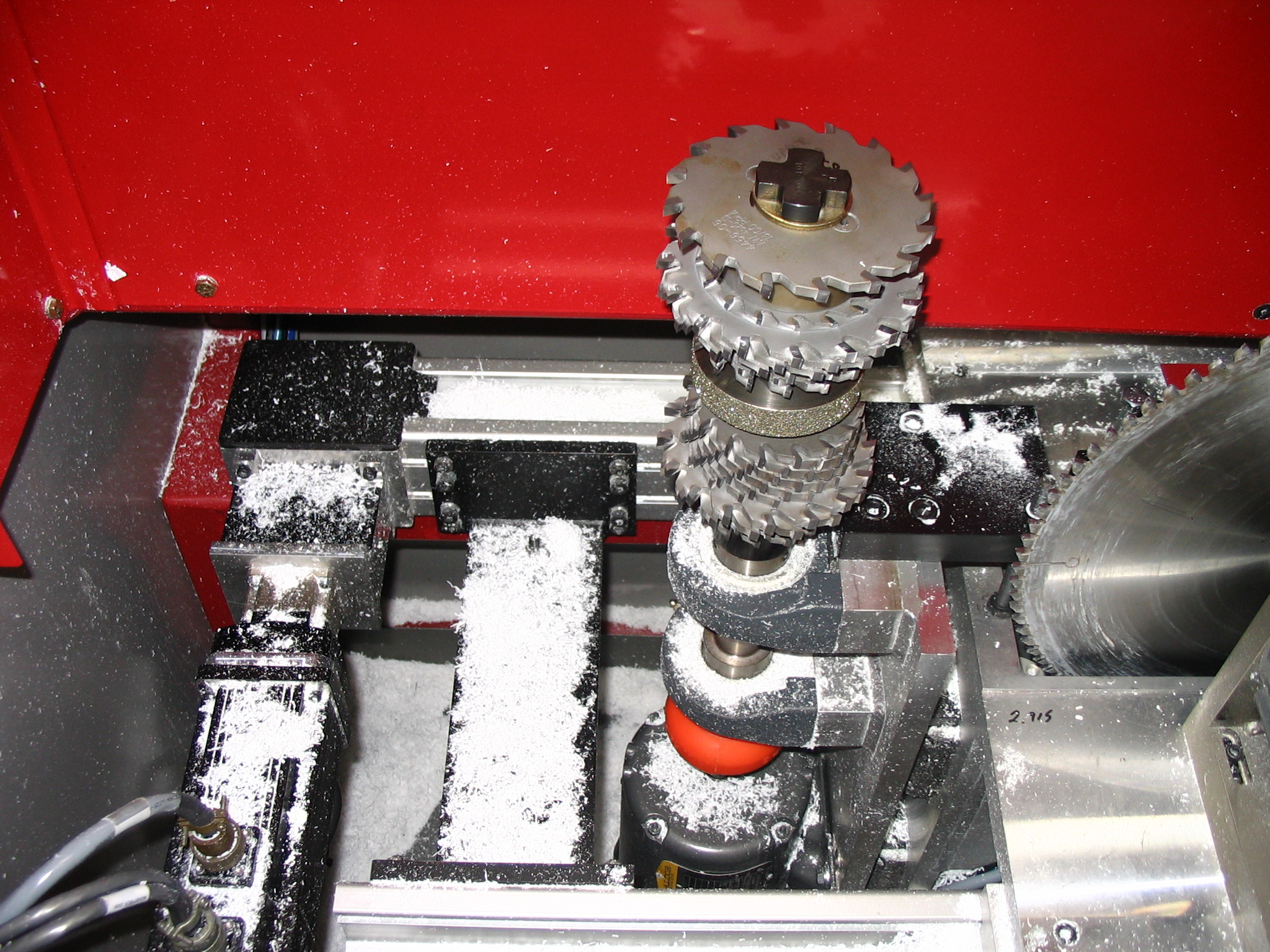

Milling head to mill pattern to trailing end of one part and leading end of the next

-

Includes SXP Automatic Profile In-feed System, utilizing Servo-driven linear actuator to automatically feed lineals into cutting area or optional secondary fabrication module(s)

-

Operator interface via industrial grade computer control

-

Optional shifting cutter stack assembly for two different mill patterns without changeover, such as for head-end and sloped sill-end processing of T-Mullions

Operator interface via industrial grade PC workstation with flat panel liquid crystal color display, touch screen functionality and Windows-based operating system.

Features:

-

12.1” Active Matrix screen

-

Pentium III 850 Mhz processor

-

Simplified user-friendly screens

-

Greater control of production data at the point of operation

-

Detailed fault screen with textmessages, pictorial trouble-shooting guidelines and direct view of PLC