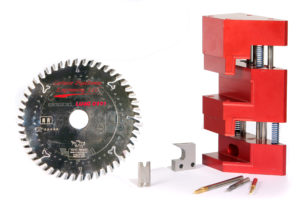

We offer a complete line of cutting tools, electrical and pneumatic parts, saw and weld fixtures, control upgrades, Teflon paper and other items to maintain and service your machines. Below is just a small sample of our offerings. Call

us to discuss your needs!

-

Leuco and Dress saw blades

-

Wemaro copy router bits

-

Tilt latch router bits

-

XYCOM and Axiom replacement computers

-

Allen-Bradley, Jetter or your preferred controllers

-

Fuses, relays, voltage converters and thermocouples

-

Saw motors and servo motors

-

THK and Star rails and bearings

-

Gear rack assemblies

-

Motor drive belts

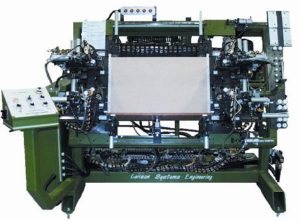

The Premier Automatic Storm Door Assembly Machine assembles wood cores, aluminum storm doors and hinge assemblies. Capacity desired per shift will determine the recommended machine for your application. Please call a representative to discuss your project.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

The ProMax Cabinet Door Pinner Plus is an affordable system that squares, clamps and fastens a variety of cabinet door styles and sizes. This machine is capable of producing 500 to 1,000 cabinet doors per eight hour shift. Standard joy stick operation allows quick and accurate size adjustments. The frame is ergonomically designed at an angle for easy placement of sub-assembled door parts and fast removal of the finished product. Operating controls are simple and convenient to minimize training time. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Overhead Mar-Proof Clamping

-

Programmable Controller

The Premier Automatic Door Pinner is designed for high volume production. The system automatically feeds the cabinet door parts on a conveyor into the machine, squares and fastens the corners and discharges the completed door onto an exit conveyor for final finishing. The doors may be open without center panels, have flat panels, or have raised center panels

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

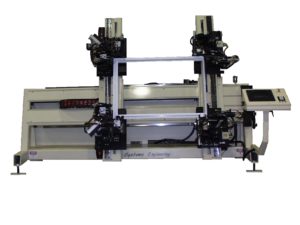

The Premier Cabinet Door Pinner squares, clamps and fastens a variety of cabinet doors in one operation. Four pneumatic tools may be adjusted to place and position one or more fasteners at each corner joint. The machine assembles most styles of cabinet door corners. The fastening in this machine is accomplished from the back side of the door, leaving the face of the door clear and unmarked for visual inspection. Standard joy stick operation allows for quick and accurate size adjustment. The four tool modules include down clamps, safety sensors and fastener placement adjustability. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

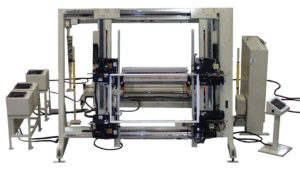

The Premier Dovetail Drawer Machine is designed to assemble drawer boxes that use dovetail, box or doweled style corner joints. The boxes need to be loosely preassembled before clamping in this machine to ensure proper joint engagement. This machine is capable of producing 800 to 1,200 drawers per eight hour shift depending on the options selected. Standard joystick operation allows for quick and accurate size adjustments. Clamping is performed by an air motor, gear box and ball screw configuration providing the clamping force needed for a single cycle sequence. Front predrills and undermount glide clearance routers can be added as options. The frame is ergonomically designed at an angle for easy placement of sub-assembled drawers and fast removal of the finished product. Operating controls are simple and convenient to minimize training time. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

The Premier Drawer Box Builder is designed to automatically fasten solid wood, MDF, or particleboard box type drawers typically covered with veneer or vinyl and having bottoms of hardboard or masonite. Machine functions are air powered with programmable electrical controls for accurate and reliable operation. The drawer box builder sets the bar in its ability to repeatedly produce square drawers with consistent fastener placement in every corner.

-

Heavy Duty Frame

-

Low Maintenance

-

Precision Linear Bearings

-

Programmable Controller

The Premier Drawer Slide Machine has been designed to predrill, clamp and fasten drawer slides to cabinet and furniture drawers. The machine design as standard has four screwdriving tools, two for each drawer slide. Each screwdriver tool can shift along the length of the drawer slide driving screws in different locations as required by the length of the drawer and slide pilot hole locations. Drills are incorporated to pre-drill pilot holes needed for the drawer slide screwdrivers. This machine is designed to accommodate different face front offsets. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

The Premier Face Frame Assembly Machine squares, clamps and fastens a variety of face frame styles in one operation. Pneumatic tools may be adjusted to place and position one or more fasteners at each corner or side joint. The machine can be designed to build many styles of face frame joints. Fastening is from the backside of the frame for a clear, unmarked face. The tool modules include square and down clamps, safety sensors and fastener placement adjustability. Standard joy stick operation allows quick and accurate size adjustments. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

The Premier Universal Drawer Machine is built for assembly line or work cell production. This machine squares, clamps and fastens a broad range of drawer sizes and styles. Once set, the machine builds mixed sizes in a single production run with simple mechanical adjustments by the operator. The machine automatically senses drawer length and height as it moves to square and clamp the parts in position and place fasteners. The completed drawer is automatically released. Clamping pressure is adjustable as needed to insure a tight joint during fastening.

-

Heavy Duty Frame

-

Low Maintenance

-

Precision Linear Bearings

-

Programmable Controller

-

Mar-Proof Product Clamping Surfaces

The ProMax Cabinet Assembly Machine is designed to clamp and hold common cabinet assemblies for manual fastening. This machine will accommodate most wall, vanity and base cabinets. Side and face frame clamping enable the operator a hands free fixture for manual fastening while insuring proper engagement and squareness of the components. Operating controls are simple and convenient to minimize training time. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Precision Linear Bearings

-

Programmable Controller

The ProMax Cabinet Door Pinner is an affordable system that squares, clamps and fastens a variety of cabinet door styles and sizes. This machine is capable of producing 500 to 1,000 cabinet doors per eight hour shift. Standard joy stick operation allows quick and accurate size adjustments. The frame is ergonomically designed at an angle for easy placement of sub-assembled door parts and fast removal of the finished product. Operating controls are simple and convenient to minimize training time. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Overhead Mar-Proof Clamping

-

Programmable Controller

The ProMax Face Frame Assembly Machine is an affordable system that squares and clamps common sizes of base and wall cabinet face frame material allowing manual fastening procedures. Production rates of 300 to 400 frames per eight hour shift are possible depending upon the frame configuration. Standard joy stick operation allows quick and accurate size adjustments. Down clamps are included to insure flush joints prior to fastening. The frame is ergonomically designed at an angle for easy placement of sub-assembled frame parts and fast removal of the finished product. Operating controls are simple and convenient to minimize training time. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

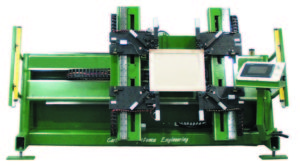

The ProMax Frame and Sash Clamp is designed to automatically clamp and fasten wood and aluminum window sashes or frames. This machine is capable of producing 400+ sashes or frames per eight hour shift depending on options selected. This semi-automatic frame clamp and sash assembly clamp features fast and infinite product height and width adjustment within the minimum and maximum constraints of the machine. The ProMax Frame and Sash Clamp is specifically designed to accommodate the fastener of your choice in the locations that you desire. The four fastening modules include fastening tools, safety sensors, fastener placement shift assemblies and down clamps. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

The Premier Frame Clamp squares and fastens a variety of materials, dimensions and cross-sections. This semi-automatic frame assembly clamp features fast and infinite product height and width adjustment within the minimum and maximum constraints of the machine. The Premier Frame Clamp is specifically designed to accommodate the fastener of your choice in the locations that you desire. The four fastening modules include fastening tools, safety sensors, fastener placement shift assemblies and down clamps. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

-

Automatic table for precise application of hot or cold sealant to glazing area

-

Sealant application capacity – 72” x 118” (73.5” maximum frame or sash width). Expanded bed model available for 96” x 118” capacity

-

Automatic height adjustment of head sensor and applicator provides a total of four axes of control – X, Y, Z1, Z2

-

Automatic corner detection and non-contact edge tracking system that compensates for bowed or skewed units for consistent application of sealant from reference edge

-

True divided light tracing capability

-

Available as a manually loaded table or with powered in- and out-feed conveyors for automated operation

-

Operator interface via industrial grade PC workstation with flat panel, liquid crystal display, touch screen functionality and operation software directly developed by Carlson Controls Engineering Group for optimum efficiency

Operator interface via industrial grade PC workstation with flat panel liquid crystal color display, touch screen functionality and

Windows-based operating system.

Features:

-

12.1” Active Matrix screen

-

Pentium III 850 Mhz processor

-

Simplified user-friendly screens

-

Greater control of production data at the point of operation

-

Detailed fault screen with text messages, pictorial trouble- shooting guidelines and direct view of PLC

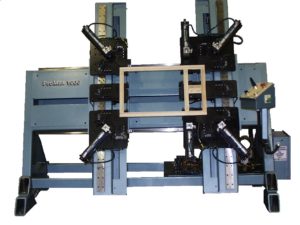

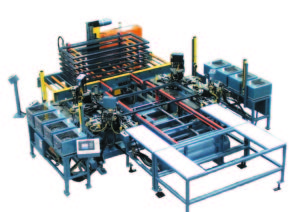

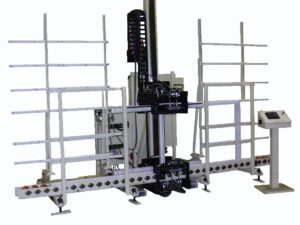

Designed for high volume advanced assembly of window frames. Sub- assembled window frame components are placed in the machine which then squares, clamps, fastens and discharges a completed frame for further assembly operations. Capable of producing 1,200 to 1,500 frames per shift.

Finish nailers, staplers, or screwdrivers may be mounted to fasten a number of corner joint styles. Fastener placement is determined by your product specifications. The four fastening modules include tools, square and down clamps, safety sensors and fastener placement controls. Powered adjustment places the fastener modules for product height and width sizes within specifications. The power adjustment keeps the frame square, true and vertically centered at a most convenient working height for operations. This machine can produce an assembled frame every 15 to 20 seconds. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy-duty frame

-

Precision linear bearings

-

Low maintenance

-

Powered size adjustments

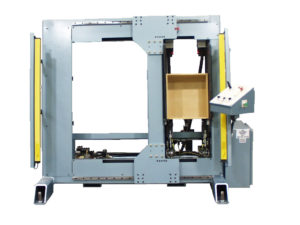

The Premier Automatic Sash Clamp is designed for a high volume production environment. To operate, a sub-assembled sash is placed on an infeed conveyor, fed into the clamp itself where it is then clamped, fastened and released onto a discharge conveyor for further assembly. Fastener placement is determined by your product specifications. Finish nailers, staplers or screwdrivers may be mounted to fasten a number of corner joint styles. The four fastening modules include tools, square and down clamps, safety sensors and fastener placement controls. Automatically powered adjustment places the fastening modules for product height and width sizes within specifications. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

The Premier Automatic Storm Door Assembly Machine assembles wood cores, aluminum storm doors and hinge assemblies. Capacity desired per shift will determine the recommended machine for your application. Please call a representative to discuss your project.

The Premier Bead Nailer is designed with a dual gantry system to fasten the glazing stops. This is an automatic machine, so there will be no setup requirements for sizing by the operator. The tool assemblies use an innovative clamping mechanism to secure the bead without making contact with the glass. This particular machine will use its horizontal flow thru conveyor systems to feed the sash into the clamp and remove the product when fastened. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

The Premier Sash Clamp squares and fastens a variety of materials, dimensions and cross-sections. This semi-automatic sash assembly clamp features fast and infinite product height and width adjustment within the minimum and maximum constraints of the machine. The Premier Sash Clamp is specifically designed to accommodate the fastener of your choice in the locations that you desire. The four fastening modules include fastening tools, safety sensors, fastener placement shift assemblies and down clamps. Machine functions are air powered with programmable electrical controls for accurate and reliable operation.

-

Heavy Duty Frame

-

Low Maintenance

-

Powered Size Adjustments

-

Precision Linear Bearings

-

Programmable Controller

-

Overhead Mar-Proof Clamping

The Premier Injection Machine is designed to hold the frame in a fixed vertical position and inject a metered amount of material into the corners of a unit at the head and sill of a window frame unit. This machine will also have a powered roller conveyor to feed frames to this station, and a powered roller exit conveyor to stage units for the next manual operation. This machine is automatically height adjustable for the height of your frames. This machine is capable of producing approximately 500 to 700 frames per shift.